Touch Screens & Touch Displays

Standard Touch Displays Make Implementation Easier

SSI provides 5 standard touch panels with integrated TFT displays and controllers, making integration easier than ever. These capacitance touch products offer universal HDMI and USB connections, allowing for more universal integration. Moreover, because these are standard products, lead‐times are short and no NRE costs apply to these touch displays.

Browse our Touch Screen Interface Product Gallery.

Here are the sizes available:

| Sizes (Diagonal) Available: | 4.3″ | 5″ | 7″ | 8″ | 10.1″ |

|---|---|---|---|---|---|

| Touch Technology | Capacitance | Capacitance | Capacitance | Capacitance | Capacitance |

| Display Type | TFT | TFT | TFT | TFT | TFT |

| Resolution | 800 x 480 | 800 x 480 | 1024 x 600 | 1024 x 768 | 1280 x 800 |

Customize to Gain Unique Features

In addition to it’s standard offerings, SSI has the ability to provide a wide variety of customized options. From size to shape, we can customize your needs at surprisingly low design and tooling costs. In addition, we can integrate these value-added options:

Popular Features

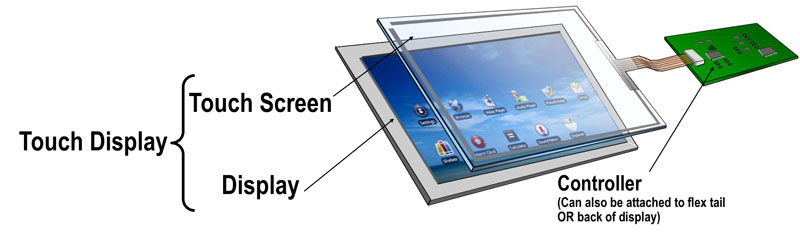

What Is the Difference Between a Touch Screen and Touch Display?

There is often confusing as to the difference between the terms touch screen, touch panel and touch displays. At SSI, we consider the touch screen to be the (top) layer that gets pressed or activated by the user. The touch screen is made up of a thin plate of glass and other transparent materials, allowing for capacitance or resistive sensing technology. The graphical or visual component of this human-machine interface sits behind the glass and is referred to as the display. The most common types of display for this application is TFT (thin film transistor) and LCD (liquid crystal display). When paired together, these two components make up a touch display.

We are able to supply you with the standalone touch screen or the more integrated version, the touch display.

Capacitance Vs. Resistance Touch Display

While there are many types of touch screen technologies, the two technologies that SSI feels are most pragmatic for it’s customers are resistance and capacitance.

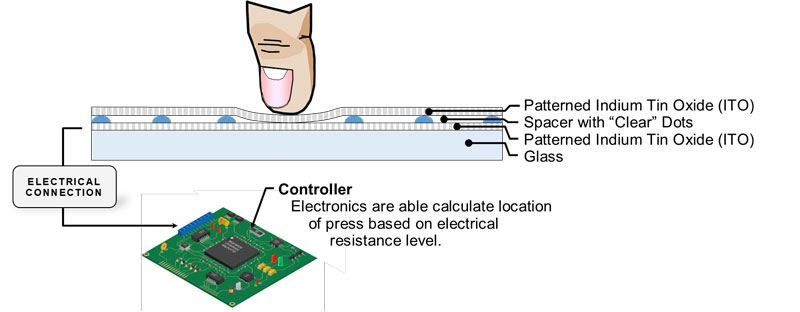

Resistive Touch Panels (or 5-Wire Resistive Touch Panels)

Resistance touch was one of the very first technology used for touch screens. It works by depositing transparent conductors on two layers of material that are separated by dielectric dots (spacer layer). The top layer is made up of a flexible material and when it is pushed it comes in contact with the bottom layer. The resistance of the conductive path that is created by the two layers indicates where on the panel the closure has been made.

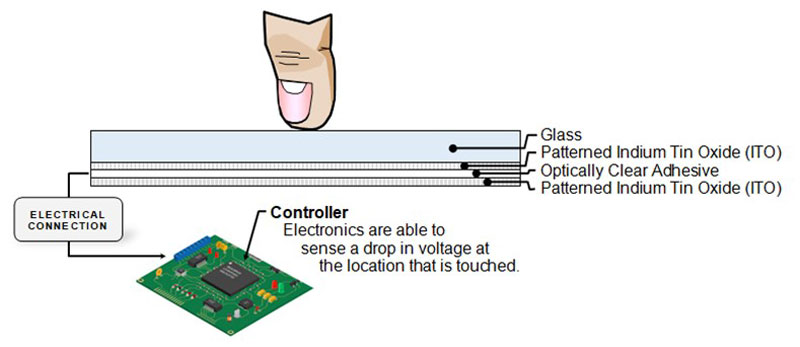

Capacitance Touch Panels (or Projected Capacitance Touch Screens—PCAP)

Different than resistive touch screens, capacitance touch screens have no moving parts. Instead, clear conductive grids connect to electronics that are able to sense a drop of voltage when the layer above it (typically glass) are touched.

Comparing Advantages of Resistive and Capacitance Touch Screens

Resistive Touch Technology

- Can be used with any stylus or tool that creates pressure

- Proven durability and longevity

- Reliable and accurate

- Resistance to dust, moisture, and other contaminants

- Lower cost than other touch panel option

Capacitance Touch Technology

- Superior accuracy and response time

- Requires less pressure to register touch screens

- Can support up to 12 multi-touch interfaces

- Continues to work even when the screen is damaged

- Higher contrast and exceptional image quality